Mastering Motor Position Control: Essential Command Guide

<!DOCTYPE html>

Achieving precise motor position control is crucial for applications ranging from robotics to industrial automation. Whether you're a beginner or an experienced engineer, understanding the essential commands and techniques can significantly enhance your system's performance. This guide will walk you through the key aspects of mastering motor position control, ensuring you have the knowledge to optimize your setups.

Understanding Motor Position Control Basics

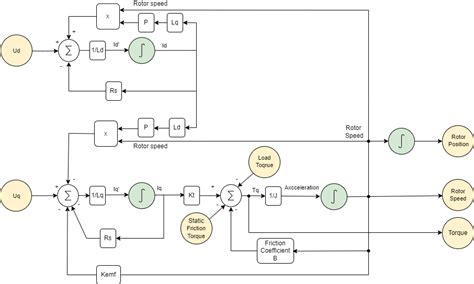

Before diving into commands, it’s essential to grasp the fundamentals of motor position control. This involves understanding the role of encoders, feedback loops, and control algorithms in achieving accurate positioning. Encoders provide real-time feedback on the motor’s position, while control algorithms adjust the motor’s movement to meet desired targets.

Key Components in Motor Position Control

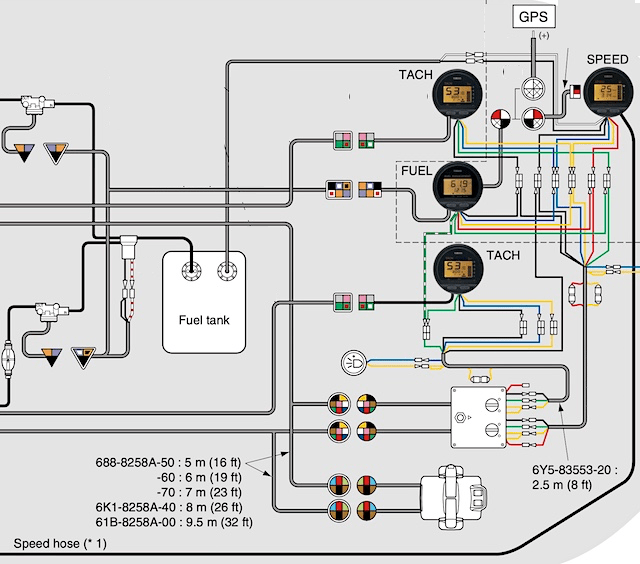

- Encoders: Measure motor position and speed.

- Controllers: Process feedback and adjust motor commands.

- Actuators: Execute the movement based on controller commands.

📌 Note: Regular calibration of encoders ensures accurate position feedback, which is critical for precise control.

Essential Commands for Motor Position Control

Mastering the right commands is key to effective motor position control. Below are some essential commands commonly used in various systems:

| Command | Description |

|---|---|

| MOVE_ABS | Moves the motor to an absolute position. |

| MOVE_REL | Moves the motor relative to its current position. |

| SET_SPEED | Sets the motor's speed for controlled movement. |

| STOP | Halt the motor immediately. |

Advanced Command Techniques

For more sophisticated control, consider using advanced commands like PID tuning and trajectory planning. PID tuning optimizes the control loop for smoother movements, while trajectory planning ensures precise path following.

📌 Note: Always test advanced commands in a controlled environment to avoid unexpected behavior.

Optimizing Motor Position Control Systems

To maximize the efficiency of your motor position control system, consider the following optimization techniques:

- Regular Maintenance: Keep motors and encoders clean and well-lubricated.

- Firmware Updates: Ensure controllers are running the latest firmware for improved performance.

- Load Matching: Match the motor's load capacity to the application requirements.

Troubleshooting Common Issues

Encountering issues is common in motor control systems. Here are some troubleshooting tips:

- Position Drift: Recalibrate encoders and check for mechanical wear.

- Jittery Movement: Adjust PID parameters for smoother control.

- Overheating: Ensure proper ventilation and check for overloading.

Mastering motor position control requires a blend of theoretical knowledge and practical skills. By understanding the basics, learning essential commands, and applying optimization techniques, you can achieve precise and reliable motor control in any application. (motor control systems,motor position feedback,PID tuning)

What is the importance of encoders in motor position control?

+Encoders provide real-time feedback on the motor's position, enabling precise control and accurate movement.

How often should I calibrate my motor control system?

+Calibration should be performed regularly, especially after maintenance or if position drift is noticed.

Can I use the same commands for different motor types?

+While some commands are universal, always refer to the motor's documentation for specific instructions.