Understanding the Head Loss Equation: A Quick Guide

<!DOCTYPE html>

Understanding the head loss equation is crucial for anyone working with fluid systems, whether in engineering, plumbing, or irrigation. This equation helps calculate the energy loss in a fluid as it flows through pipes, fittings, or other components. By mastering this concept, you can optimize system efficiency, reduce energy costs, and ensure proper fluid flow. In this guide, we’ll break down the head loss equation, its components, and how to apply it effectively. (head loss calculation, fluid dynamics, pipe flow efficiency)

What is the Head Loss Equation?

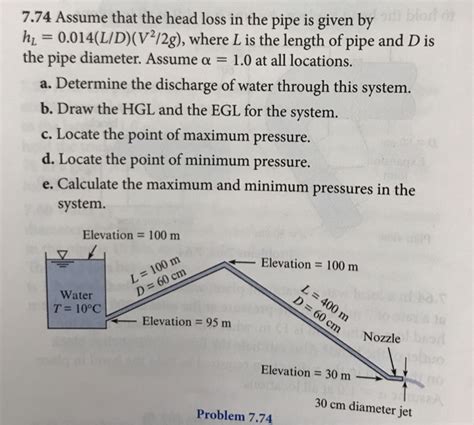

The head loss equation is a fundamental formula in fluid mechanics used to determine the pressure or energy drop in a fluid due to friction and other resistances. It’s expressed as:

hL = f * (L/D) * (v2/2g)

Where:

- hL = Head loss (meters)

- f = Friction factor (dimensionless)

- L = Length of the pipe (meters)

- D = Diameter of the pipe (meters)

- v = Velocity of the fluid (m/s)

- g = Acceleration due to gravity (9.81 m/s²)

💡 Note: The friction factor (f) depends on the pipe’s roughness and flow regime, often determined using the Moody chart or Darcy-Weisbach equation.

Key Components of Head Loss

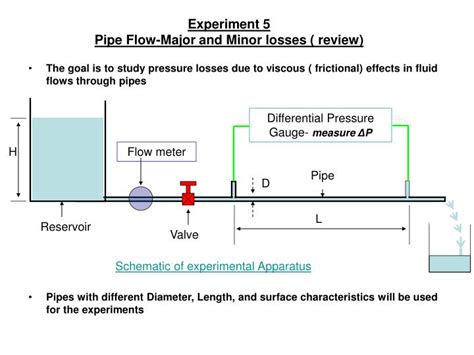

Head loss occurs due to two main factors: major losses and minor losses.

Major Losses (Frictional Losses)

These are caused by the fluid’s friction against the pipe walls and are calculated using the head loss equation. They depend on the pipe’s length, diameter, fluid velocity, and roughness. (frictional head loss, Darcy-Weisbach equation)

Minor Losses

These occur due to fittings, valves, bends, or changes in pipe diameter. Minor losses are typically expressed as:

hL,minor = K * (v2/2g)

Where K is the loss coefficient, specific to the type of fitting or component. (minor head loss, loss coefficient)

How to Apply the Head Loss Equation

To apply the head loss equation effectively, follow these steps:

- Determine Flow Parameters: Measure or calculate the fluid velocity, pipe dimensions, and flow regime.

- Calculate the Friction Factor: Use the Moody chart or Colebrook-White equation to find the friction factor (f).

- Compute Major Losses: Plug the values into the head loss equation to calculate frictional losses.

- Account for Minor Losses: Identify fittings and use their loss coefficients to calculate minor losses.

- Sum Total Head Loss: Add major and minor losses to get the total head loss in the system.

Practical Tips for Minimizing Head Loss

Reducing head loss is essential for improving system efficiency. Here are some actionable tips:

- Use larger diameter pipes to reduce velocity and friction.

- Minimize the number of fittings and bends in the system.

- Select pipes with smooth interior surfaces to lower the friction factor.

- Regularly clean pipes to prevent buildup and maintain flow efficiency.

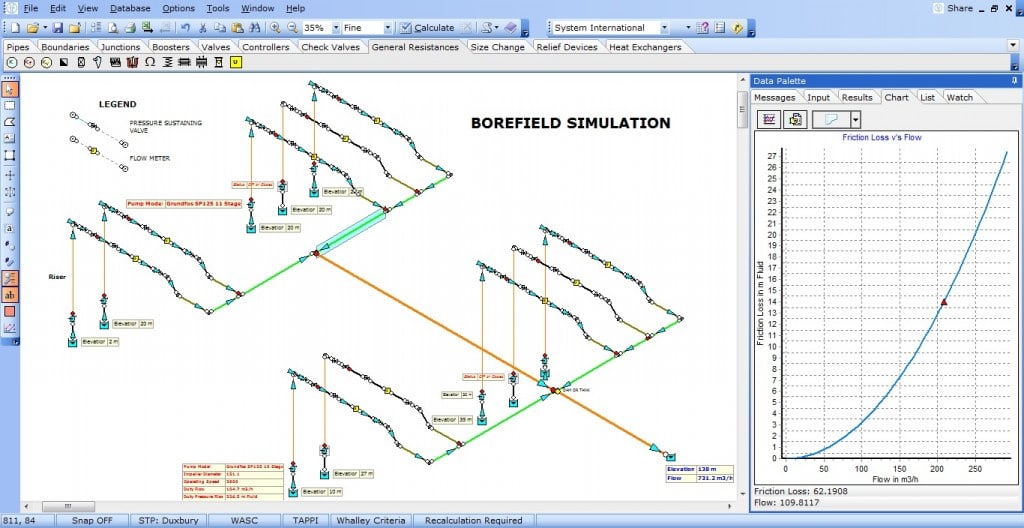

Head Loss Equation in Real-World Applications

The head loss equation is widely used in industries such as:

| Industry | Application |

|---|---|

| HVAC Systems | Optimizing air and water flow in heating and cooling systems. |

| Water Treatment | Ensuring efficient fluid movement through filtration and distribution systems. |

| Oil & Gas | Managing fluid flow in pipelines and refineries. |

Understanding and applying the head loss equation is essential for designing and maintaining efficient fluid systems. By mastering its components and practical applications, you can reduce energy consumption, minimize costs, and ensure optimal performance. (fluid systems optimization, energy efficiency in piping)

What causes head loss in a pipe system?

+Head loss is primarily caused by friction between the fluid and pipe walls (major losses) and resistance from fittings or bends (minor losses).

How can I reduce head loss in my system?

+Use larger pipes, minimize fittings, maintain smooth pipe surfaces, and regularly clean the system to reduce head loss.

What is the difference between major and minor head losses?

+Major losses are due to friction along the pipe, while minor losses result from fittings, valves, or changes in pipe geometry.