Aluminum Linear Expansion Coefficient: Key Facts & Uses

Understanding the aluminum linear expansion coefficient is crucial for engineers, designers, and manufacturers working with aluminum materials. This coefficient measures how much aluminum expands or contracts with temperature changes, a key factor in ensuring structural integrity and performance. Whether you're designing precision components or large-scale structures, knowing this value helps prevent failures and optimizes material use. Below, we explore essential facts and practical applications of this critical property, tailored for both informational and commercial audiences.

What is the Aluminum Linear Expansion Coefficient? (aluminum properties,thermal expansion)

The aluminum linear expansion coefficient quantifies how much aluminum expands per degree Celsius or Fahrenheit. Typically denoted as α, this value is approximately 23.1 × 10⁻⁶ /°C. It’s essential for predicting dimensional changes in aluminum components under varying temperatures, ensuring they function as intended in different environments.

Key Facts About Aluminum’s Thermal Expansion (thermal expansion,aluminum alloys)

- Low Expansion Rate: Aluminum has a lower expansion coefficient compared to materials like steel, making it ideal for applications requiring dimensional stability.

- Alloy Variations: Different aluminum alloys may have slightly different expansion coefficients due to their composition. For example, 6061 aluminum has a coefficient of 23.6 × 10⁻⁶ /°C.

- Temperature Sensitivity: Aluminum’s expansion is directly proportional to temperature changes, making it critical to account for in high-temperature applications.

Practical Uses of Aluminum’s Expansion Coefficient (engineering applications,aluminum manufacturing)

The aluminum linear expansion coefficient is vital in various industries:

- Construction: Ensures proper spacing in aluminum windows, doors, and structural components to avoid warping.

- Automotive: Used in designing engine parts and body panels to withstand temperature fluctuations.

- Electronics: Critical for maintaining precise dimensions in heat sinks and enclosures.

How to Calculate Thermal Expansion in Aluminum (thermal expansion formula,aluminum engineering)

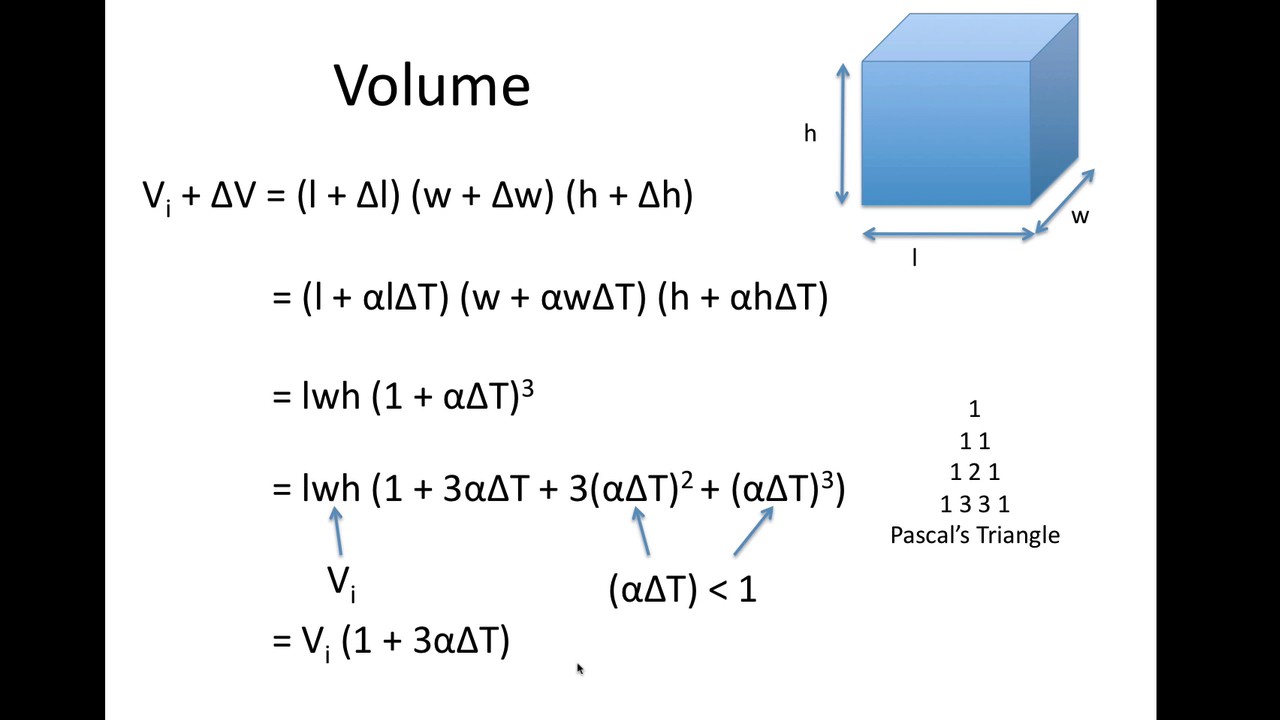

The formula for linear thermal expansion is:

ΔL = α × L₀ × ΔT

Where:

- ΔL = Change in length

- α = Linear expansion coefficient

- L₀ = Original length

- ΔT = Temperature change

📘 Note: Always use consistent units (e.g., °C for temperature and meters for length) to ensure accurate calculations.

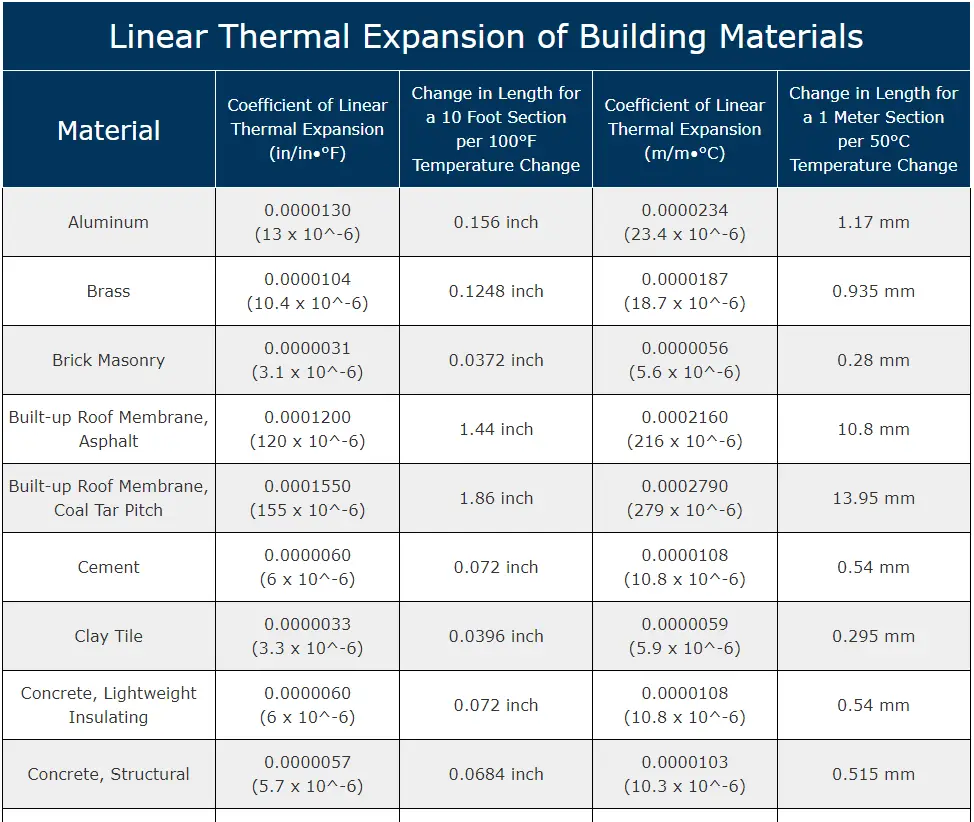

| Alloy | Expansion Coefficient (/°C) |

|---|---|

| 1100 | 23.1 × 10⁻⁶ |

| 6061 | 23.6 × 10⁻⁶ |

| 7075 | 22.4 × 10⁻⁶ |

Checklist: Key Considerations for Using Aluminum (aluminum design,material selection)

- Verify the expansion coefficient of the specific aluminum alloy.

- Account for temperature extremes in your design.

- Include expansion joints or allowances in large structures.

- Test prototypes under real-world temperature conditions.

The aluminum linear expansion coefficient is a fundamental property that impacts the design and functionality of aluminum components. By understanding its value and applications, engineers and manufacturers can ensure durability and performance in various industries. Whether you're working on construction projects, automotive parts, or electronic devices, this knowledge is indispensable for success.

What is the aluminum linear expansion coefficient?

+The aluminum linear expansion coefficient is approximately 23.1 × 10⁻⁶ /°C, indicating how much aluminum expands per degree Celsius.

How does aluminum’s expansion coefficient compare to steel?

+Aluminum has a lower expansion coefficient than steel, making it more dimensionally stable under temperature changes.

Why is the expansion coefficient important in engineering?

+It helps engineers predict dimensional changes in aluminum components, preventing failures and ensuring proper functionality.